In a world that depends heavily on plastic components, the plastic molding machine has emerged as a pivotal technology in manufacturing. From daily household items to automotive parts and industrial components, this machine enables manufacturers to produce high-quality plastic products with speed, precision, and consistency.

What Is a Plastic Molding Machine?

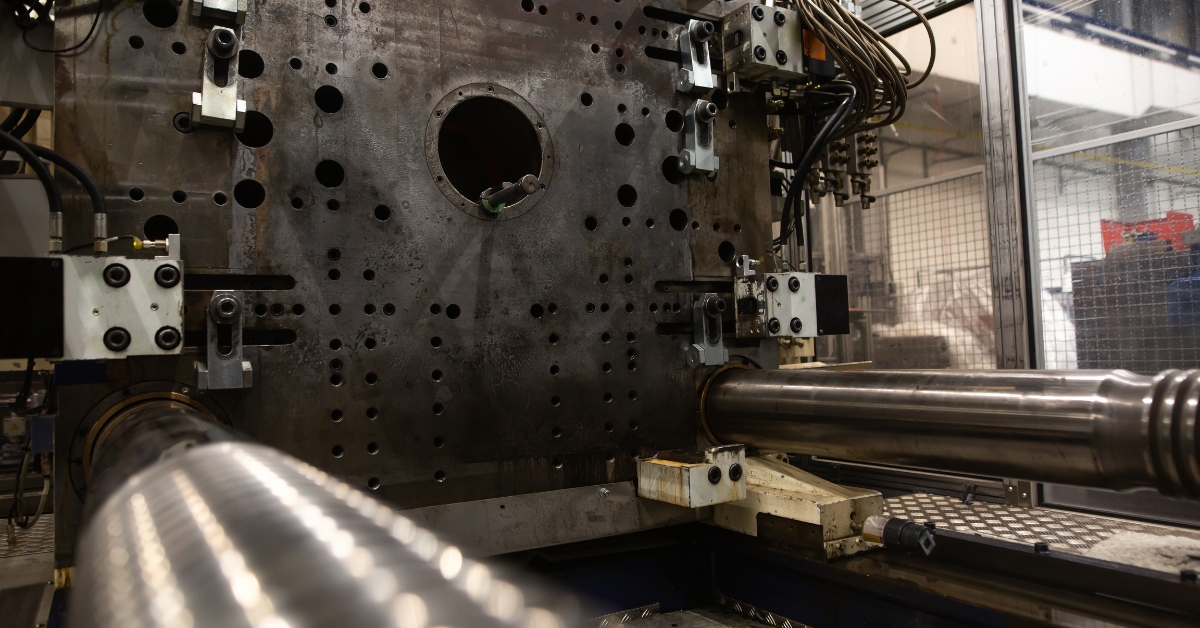

A plastic molding machine is a type of industrial equipment designed to shape plastic materials into desired forms by applying heat and pressure inside a mold cavity. The machine melts plastic pellets or granules and forces the molten plastic into a mold. Once cooled, the mold opens to release the final product.

This process is foundational in various industries, making plastic molding machines essential for efficient, large-scale production.

Types of Plastic Molding Machines

There are several types of machines used in the plastic molding industry, each serving a specific need:

- Injection Molding Machine: Ideal for creating high-precision parts in large quantities.

- Blow Molding Machine: Used for producing hollow items like bottles and containers.

- Compression Molding Machine: Commonly used in automotive and electrical industries.

- Extrusion Molding Machine: For continuous plastic profiles like pipes or sheets.

- Rotational Molding Machine: Produces large, hollow objects such as tanks.

Each type of plastic molding machine is tailored to particular product requirements, production volumes, and material types.

Key Advantages of Using Plastic Molding Machines

Manufacturers choose plastic molding machines for several strategic advantages:

- Mass Production Capability: Create thousands of identical parts efficiently.

- Material Efficiency: Less waste through controlled injection and recycling.

- High Design Flexibility: Support for complex and detailed mold designs.

- Improved Cycle Time: Fast turnaround per part lowers production costs.

- Minimal Post-Processing: Parts often need little to no finishing after molding.

These benefits make plastic molding machines indispensable in sectors where speed, accuracy, and volume matter.

Industries That Rely on Plastic Molding

The reach of plastic molding machines is broad and constantly expanding:

- Consumer Electronics: Casings, buttons, and internal mounts.

- Medical Devices: Syringes, tubing connectors, and housing units.

- Automotive: Bumpers, dashboards, and interior panels.

- Packaging: Bottles, caps, trays, and containers.

- Construction: Pipe fittings, clips, and panel components.

- Furniture: Seats, backs, and structural supports.

With growing demand for plastic products, these machines provide a scalable solution to meet evolving market needs.

Internal Components and Their Functions

Understanding how a plastic molding machine operates requires a look at its core components:

| Component | Functionality |

|---|---|

| Hopper | Feeds raw plastic granules into the machine. |

| Heating Unit | Melts the granules to prepare for molding. |

| Injection System | Pushes the molten plastic into the mold cavity. |

| Mold Clamping Unit | Holds the mold in place during injection and cooling. |

| Ejection System | Removes the final product from the mold once it’s solidified. |

These elements work in sync to ensure every molded part meets exact specifications and quality standards.

Step-by-Step Molding Process

- Feeding: Raw plastic is poured into the hopper.

- Melting: The granules pass through a heated barrel and melt.

- Injection: Molten plastic is injected into the mold cavity.

- Cooling: The mold remains closed while the plastic solidifies.

- Ejection: The final product is released from the mold.

- Repeat: The cycle continues for the next item.

This closed-loop system ensures reliable output with minimal material waste.

Choosing the Right Plastic Molding Machine

Several factors influence the right machine selection:

- Product Size: Larger parts require higher clamping force.

- Production Volume: Determines the need for automation and speed.

- Material Type: Not all machines handle every plastic resin.

- Mold Design: Complex molds may need advanced machine features.

- Budget: Upfront cost vs. long-term operational efficiency.

Working with experienced manufacturers helps streamline this decision-making process. For tailored solutions, Daoben Machinery offers high-performance plastic molding machines that meet industry-specific needs.

Innovation in Plastic Molding Machinery

Today’s plastic molding machines are undergoing rapid innovation:

- Electric and Hybrid Machines: Greater energy efficiency and precision.

- Smart Controls: Advanced touchscreens and data analytics systems.

- Predictive Maintenance: Using sensors to detect wear and prevent failures.

- Material Advancements: Compatibility with biodegradable plastics and composites.

These upgrades not only enhance productivity but also align with sustainability goals, helping manufacturers reduce their environmental footprint.

Maintenance and Long-Term Operation

To ensure optimal performance and machine longevity:

- Regular Inspection of heating units and screw components.

- Lubrication of moving parts to reduce friction.

- Monitoring of temperature and pressure consistency.

- Timely Replacement of worn-out parts.

- Training Operators on correct handling and safety protocols.

Routine care prevents downtime and increases the return on investment over time.

Conclusion

The plastic molding machine plays a central role in modern manufacturing by enabling large-scale, high-quality plastic part production. With continued innovation and rising global demand for plastic components, these machines remain critical assets across multiple industries. For manufacturers seeking reliable, scalable solutions, Daoben Machinery provides the engineering expertise and cutting-edge equipment to support growth in any production environment.